Basic Info

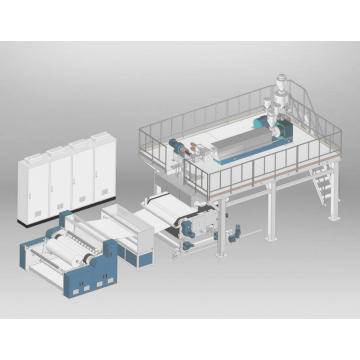

Model No.: 1600 2400 3200mm

Click on the follow link to find out more information: http://www.xzsnonwovenmachine.com/meltblown-line-series/

Company Info

- Company Name: Changzhou Xinzhongshun Nonwoven Machinery Co., Ltd.

- Representative: Xu Wu

- Product/Service: Nonwoven Machine , pp ss Nonwoven Fabric Machine , pp spubond and melt blown composite smms line , Epidemic Prevention Production Machinery , sms pp Nonwoven Fabric Machine , pp sms spubond nonwoven fabric maikng machine seri

- Capital (Million US $): 10,000RMB

- Year Established: 2005

- Total Annual Sales Volume (Million US $): Below US$1 Million

- Export Percentage: 1% - 10%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 11

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): Below 1,000 square meters

- Factory Location: Nantong Cotton Machinery Co., Ltd. West Gate

- Contact Person: Mr. wu

- Tel: 86-13862942024

Premium Related Products

Other Products

Hot Products

Welded Silver White Steel Bar Grating Mesh ProductsStainless Steel Mesh Dutch Woven Wire Mesh2015 professional and practical Hexagonal Wire MeshPerforated stainless steel metal wire meshSteel 304 Perforated Metal Mesh/ Perforated Metal Sheets ,plates made in chinaalibaba china Low price Barbecue wire mesh/stainless steel barbecue bbq grill wire mesh netHot Protective High Rust Chain Link Fence Supplieralibaba china Supply super cheapest Electric Grassland Field Fence/galvanized wire fencing (Manufacturer)aluminum chain curtain/models curtain room divider/metalic chain link curtainsmesh bag steel wire basket alibaba chinawire mesh cage screen mesh flexible meshHigh quality stainless steel wire mesh for plant supportEnclosures foe aviary stainless steel wire fence netStainless steel chainmail pot cookware for brushPopular woven technique stainless steel wire meshChina baina export high-class quality stainless steel wire fence